Custom Formulation & Testing of High-Temperature Ink for Aluminum Zirconium Silicate Substrate for the Glass Industry

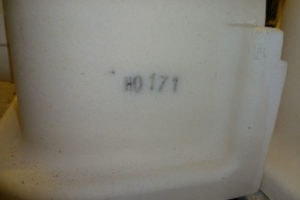

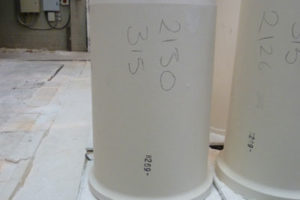

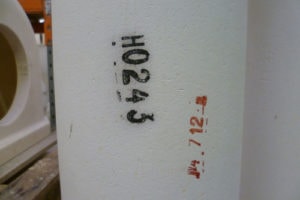

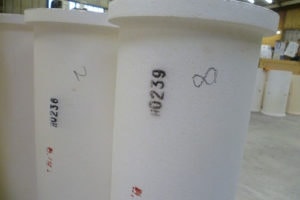

A client in the United Kingdom had been marking product codes and batch numbers into its ceramics in the green state using a sharp tool. The problem with scratching is that it can time consuming, the numbers can easily be removes if handle in the area of the mark before fire, and also can be very difficult to locate after fire. Our black 66W201 DuraFire™ marking ink was applied to the client’s aluminum zirconium silicate substrate and fired at 1510°C at which point the markings became permanent. Our water-based, non-toxic ink is also zero VOC and can be cleaned up with water.

Stamping the relevant codes and batch numbers proved to be a much faster and easier alternative to scratching them in while also producing a very durable, permanent record. The customer was pleased with the ease of application as well as the legibility and durability of the ink.

We have provided additional details on the project below, and would be pleased to discuss your specific needs with you.